When measuring the level of liquids and bulk solids, there are several ways in which to obtain accurate results. But in this article by EMC Industrial Group, we’ll be specifically focusing on hydrostatic level measurements; what it is, the benefits, and how you can get the most precise and reliable results using this method.

At EMC Industrial Group, we offer a wide range of level measuring equipment in New Zealand, and are experts on this topic.

What is Hydrostatic Level Measurement?

Hydrostatic level measurement is a form of continuous liquid level measurement that makes use of pressure sensors. These sensors are used in a wide variety of industries such as wastewater, food, and water. They can be used to measure water or any other liquid.

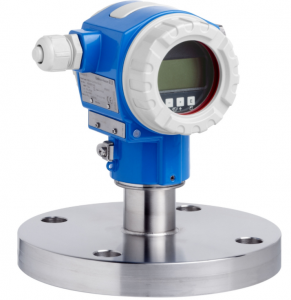

These sensors are usually located in tanks (flanged), or wells, rivers and lakes (submersible cable versions). Whatever your application, there is a hydrostatic measuring device best suited to your requirements.

The cells used in the sensors are either metallic, oil filled, or ceramic. The principle works by pressure applied to the isolating diaphragm which is detected by the sensor which can be either piezoresistive or capacitance.

The Benefits of Hydrostatic Level Measurement Equipment

Some of the benefits associated with this type of level measurement equipment include:

- Robust, durable sensors that can stand abrasion

- Wide variety of materials making them compatible with most chemicals

- Ceramic cells are ideal for vacuum applications with no fluid filling

- Breakage detection is integrated

- Performs well in condensing conditions

Ensuring Your Measurements are Accurate

Hydrostatic level measurement systems are influenced by:

- Density of the medium

- The Medium temperature (which will in turn affect the density)

It is important to consider if the medium density is consistent and stable, especially if the medium changes its composition. This is often the case in Wastewater applications etc.

Increasing the media temperature also means that the density reduces but at the same time the liquid level increases. In this case the liquid level may not be entirely accurate if the sensor has been calibrated to a certain density. However the measurement of the overall mass (ie. kg) of the product in the vessel remains unchanged. The size and shape of the tank will also play a role in the fluctuation of level measurement however the output can be linearised to allow for any tank shape.

Compensating for changes in temperature and density can be tricky but is absolutely necessary if you are after precise results. We can help you overcome these issues.

Learn more by visiting https://www.endress.com/en/field-instruments-overview/pressure/Hydrostatic-level-measurement

Are you looking for hydrostatic level measurement devices in New Zealand? Here at EMC Industrial Group we offer a wide range of different level measurement equipment. Browse our website or get in touch with us to learn more!